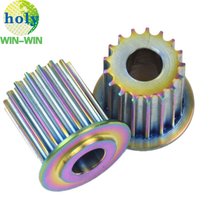

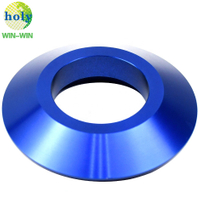

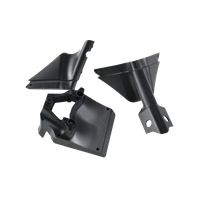

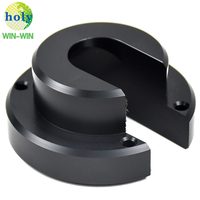

Holy Precision CNC Turning Service

CNC turning parts is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret with tooling of CNC turning parts attached is programmed to move to the bar of raw material and remove material to create the programmed result. CNC turning parts is also called “subtraction machining” since it involves material removal.

English

English 简体中文

简体中文