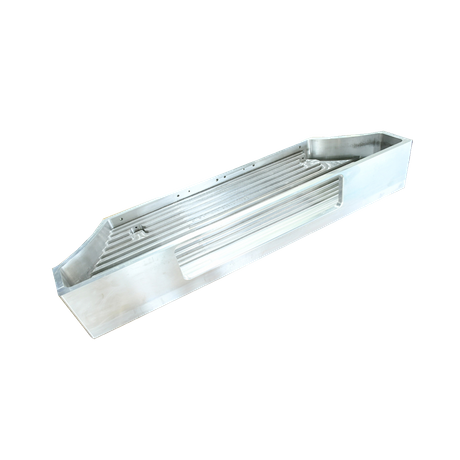

Laser cutting service is a specialized workshop that provides precision laser cutting of metal. We have a large inventory of carefully selected products including steel, alloy, stainless steel, aluminum and brass. Our dedicated team of sales professionals, programmers, machine operators and material handlers has expertise in a wide range of applications from art to aerospace.

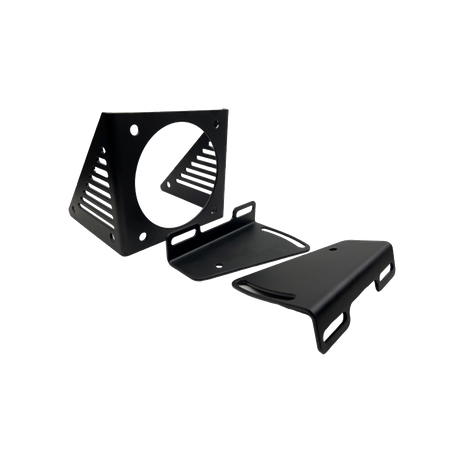

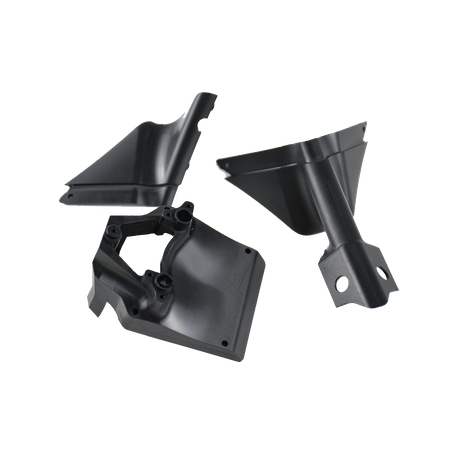

Stamping can produce finished metal parts faster than any other metal processing. It produces hundreds of millions of stampings every year for the appliance, electronics and automotive industries. The stamping process combines traditional and progressive stamping tools in the press to punch and shape the product from sheet metal parts.

22 Years Professional Manufacturer

Focus On OEM &

ODM

Quality Comes

First

Certification: ISO, SGS, TUV

Strict Quality Control Process

Communication-always Clear And Efficient

Sample Offered: Within Today

Before-sale service:

Our company has professional and experienced sales representatives who can answer your questions about parts and provide you with the different workable solutions to solve the problems and help to meet your expectation and budget.

After-sale service:

We attach great importance to the feed backs from our customers after they received the parts, will respond promptly to the service request from our customers and settle the problems in time. In addition, any reasonable comments and suggestions from customers will be highly Appreciated and we’ll adopt them to improve our service for you better.