Views: 0 Author: Site Editor Publish Time: 2025-09-20 Origin: Site

The Open Factory Revolution: How Multi-Brand Orchestration Unlocks 40% Productivity Surge For Automotive, Semiconductor & Medical OEMs Battling Fragmented Automation

In 2025, manufacturing’s greatest bottleneck is no longer hardware capability—it’s interoperability. While 73% of plants operate AGV/AMR fleets from 5+ vendors, 68% suffer daily collisions or idle time due to protocol fragmentation . Holy Precision’s Open Automation Ecosystem transforms this chaos into seamless synergy, enabling Mitsubishi robots, Siemens PLCs, and Fanuc arms to collaborate like a single organism—proven to slash downtime by 40% and boost throughput by 25%.

The $1.2M/Hour Cost of Fragmentation Legacy “walled garden” automation inflicts three lethal wounds:

Device Incompatibility: AGVs from Brand A halt when Brand B’s AMR blocks a path—costing auto plants $220K/day in stalled logistics.

Data Silos: MES/ERP systems blind to equipment status cause 30% overstocking or shortages in medical device assembly.

Rigid Architectures: Semiconductor fabs require 3-week reconfiguration to add new metrology tools—delaying 3nm chip ramps.

Holy Precision’s antidote: Universal Interoperability Layer + AI Dynamic Scheduler + Unified Digital Twin.

Three Pillars of the Truly Open Factory

① Multi-Brand Robot Orchestration

Inspired by Pangolin ADS (100+ brand compatibility) and Guozi Robotics’ swarm intelligence, our platform enables:

Protocol-agnostic integration: Translate proprietary languages (FANUC FOCAS, KUKA KLI) into unified API commands—cutting integration time from weeks to hours .

Conflict-free pathing: AI scheduler allocates tasks via real-time traffic optimization, as proven in a Tier-1 auto plant (2000+ daily AGV missions, zero collisions)

Hardware-agnostic control: Command Yaskawa arms via Rockwell Logix PLCs using PointMax™ I/O’s flexible topology—eliminating control cabinet spaghetti.

② Data Fusion Engine

Beyond Durst’s Smart Factory OS, we deploy blockchain-secured data pipelines:

Live MES/ERP synchronization: Sync material demand signals with equipment status at 50ms latency—reducing WIP inventory by 33% at a Siemens-certified plant.

Predictive compliance: Auto-generate FDA/AS9100 audit trails using embedded traceability logs (e.g., ≤2μm positioning accuracy records for medical devices) .

Energy-intensity decoupling: Monitor motor power draw via PI direct-drive actuators—cutting semiconductor fab energy use by 40% .

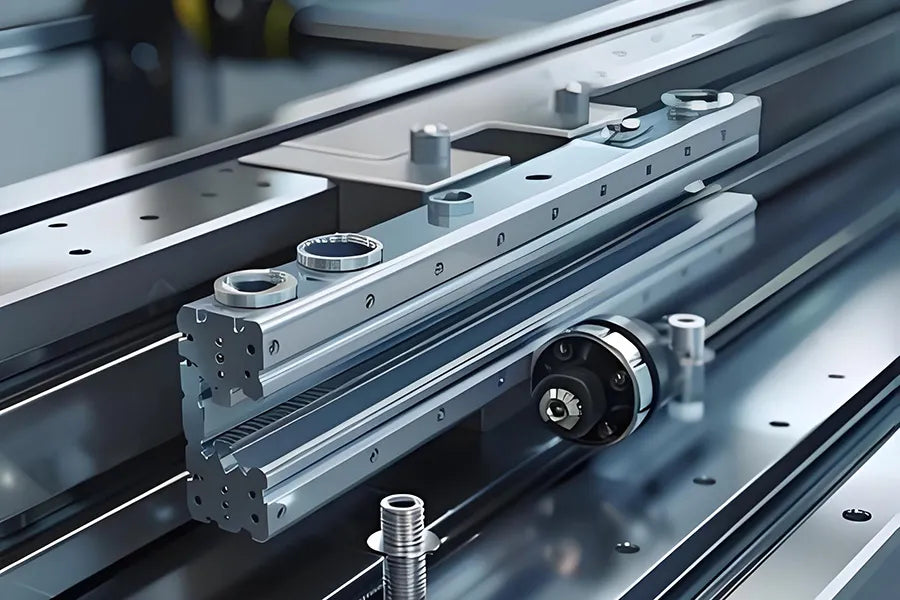

③ Precision Motion Hyperintegration

Leveraging Hanno’s micron-grade screw modules (±3μm repeatability) and Mettop’s vision-guided robotics, we unify:

Sub-micron alignment: 6D laser trackers calibrate cobot paths in real-time for medical catheter assembly (0.02mm bubble defect detection) .

Zero-retooling changeovers: Switch EV battery module formats in 8 minutes using magnetic kinematic couplings—vs. industry standard 8 hours .

Self-healing accuracy: Thermal drift compensated at 500Hz via digital twin feedback, maintaining 0.01mm tolerance in aerospace grinding .