Views: 0 Author: Site Editor Publish Time: 2025-02-13 Origin: Site

The Future of CNC Machining: Top Trends Shaping the Industry in 2025

The world of CNC machining is evolving faster than ever, driven by technological advancements and growing demands for precision, efficiency, and sustainability. As we move further into 2025, several key trends are reshaping the industry. Let’s dive into the hottest topics in CNC machining right now!

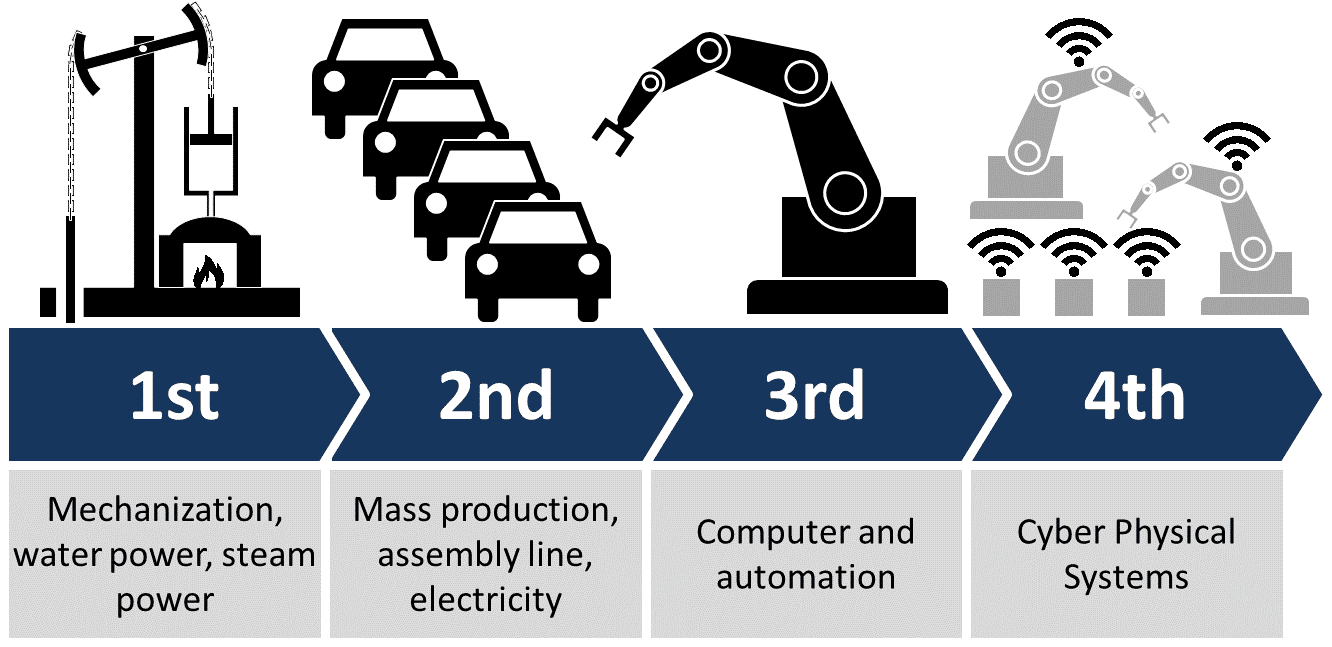

• The Rise of Smart Factories and Industry 4.0

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) into CNC machining is revolutionizing production. Smart factories now use connected machines that communicate in real-time, optimizing workflows, predicting maintenance needs, and reducing downtime. This shift toward Industry 4.0 is making manufacturing smarter, faster, and more efficient.

• 5-Axis Machining Goes Mainstream

Once reserved for high-end applications, 5-axis CNC machining is becoming more accessible and affordable. This technology allows for the creation of highly complex parts in a single setup, reducing production time and improving accuracy. Industries like aerospace, medical, and automotive are embracing 5-axis machining for its ability to handle intricate designs with ease.

• Sustainability in CNC Machining

As environmental concerns grow, the manufacturing industry is focusing on sustainable practices. CNC machining is no exception. Companies are adopting energy-efficient machines, recycling metal waste, and using eco-friendly coolants. Additionally, the demand for lightweight, durable materials like titanium and composites is rising, as they contribute to fuel efficiency in aerospace and automotive applications.

• Additive Manufacturing Meets CNC Machining

The combination of 3D printing (additive manufacturing) and CNC machining is creating new possibilities. Hybrid machines that can both 3D print and perform precision machining are gaining traction. This approach allows for the production of complex, custom parts with reduced material waste and shorter lead times.