Views: 0 Author: Site Editor Publish Time: 2025-12-31 Origin: Site

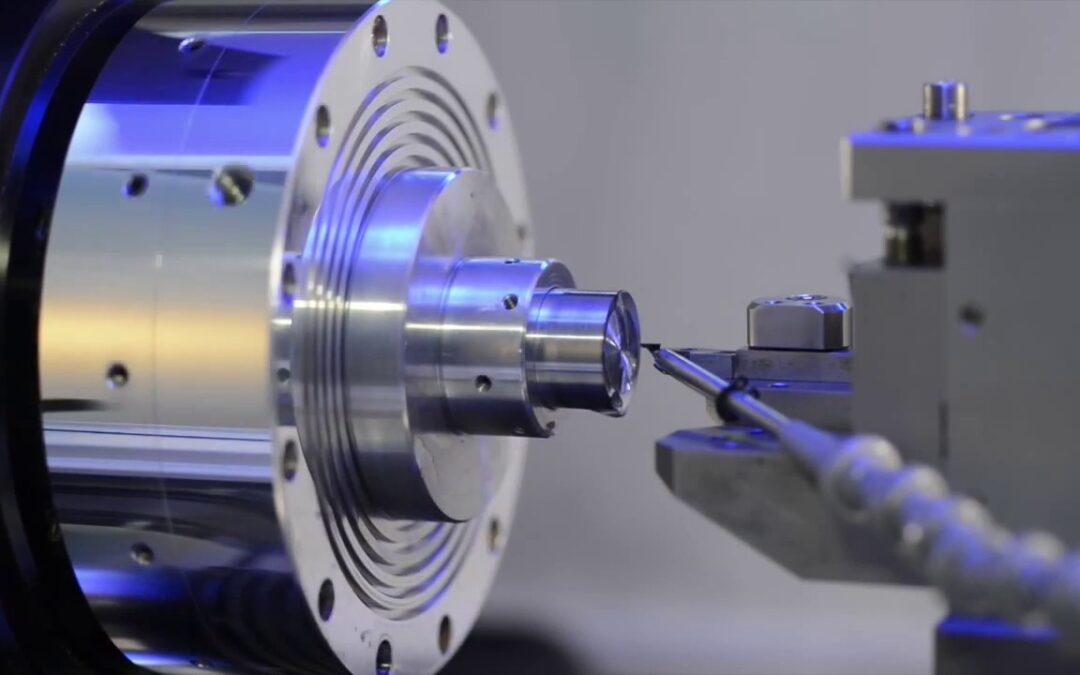

Aluminum remains the quintessential material for modern engineering, perfectly balancing low density, excellent strength-to-weight ratios, and superior machinability. In the era of electrification, aerospace innovation, and miniaturization, precision CNC machining has elevated aluminum from a common metal to the backbone of high-performance applications. The challenge is no longer just to cut aluminum, but to machine it with micron-level accuracy, repeatability, and efficiency that meets the most demanding industry standards.

The demand for precision in aluminum parts has escalated due to several converging trends:

Electrification & Lightweighting: Electric vehicle battery enclosures, motor housings, and thermal management plates require intricate cooling channels, precise sealing surfaces, and dimensional stability over large spans. A deviation of 0.05mm in a battery cell's seating surface can compromise safety and performance.

Aerospace & Defense: From satellite brackets to UAV fuselage components, every gram saved translates to fuel efficiency and payload capacity. These parts often feature complex, thin-walled geometries that demand near-net-shape machining with tolerances tighter than ±0.025mm to maintain structural integrity.

Advanced Optics & Semiconductors: Mounting plates and chambers for sensitive equipment must exhibit exceptional flatness (often < 5μm over 300mm), minimal residual stress, and vibration-damping characteristics, which are achieved through specific machining and post-processing protocols.

Achieving consistent, high-precision results in aluminum requires a holistic approach that integrates advanced hardware, optimized software, and deep process knowledge.

Machine Tool Foundation: Precision starts with the machine. For aluminum, this means:

High-Speed Spindles (20,000+ RPM): Essential for maintaining optimal surface feet per minute (SFM) with small-diameter tools, especially for fine-detail engraving and high-efficiency milling (HEM).

Thermal Stability & Rigidity: Machines with symmetric cooling systems, polymer-concrete bases, and direct-drive motors counteract the heat and vibration that erode precision over long machining cycles.

5-Axis Capability: Essential for complex parts, allowing for single-setup machining that eliminates cumulative errors from multiple fixturings.

Cutting Tool Strategy: The right tool is a precision instrument.

Uncoated & PCD Tools: For most high-finish applications, micro-grain uncoated carbide provides the sharpest edge. For high-volume production or machining abrasive silicon-aluminum alloys, Polycrystalline Diamond (PCD) tools offer unmatched life and consistent finish.

Toolpath Engineering: Modern CAM software uses adaptive clearing and trochoidal milling paths to maintain constant tool load, reduce heat, and extend tool life while removing material at unprecedented speeds.

Process Control & Metrology: Precision must be verified, not assumed.

In-Process Probing: Touch-trigger probes automatically set workpiece zeros, measure critical features mid-cycle, and compensate for tool wear in real-time.

Post-Process Validation: High-accuracy CMMs, laser scanners, and optical comparators provide full First Article Inspection (FAI) reports, ensuring compliance with GD&T callouts on even the most complex drawings.

Not all aluminum is created equal. The choice of alloy directly impacts machinability, final strength, and anodizing quality.

The final surface treatment is a critical extension of the machining process.

Machined Finish: Directly from the CNC, achieving Ra 0.4 - 0.8 μm is standard for precision parts. Through careful toolpath control and parameter tuning, Ra < 0.2 μm is attainable for optical surfaces.

Anodizing (Type II & III): The go-to finish for wear and corrosion resistance. Precision machined parts provide the ideal substrate for a consistent, high-quality anodic layer. Hardcoat (Type III) can increase surface hardness to over 500 Vickers.

Media Blasting & Vibratory Finishing: Used to create uniform matte surfaces, deburr complex internal channels, and induce beneficial compressive surface stresses.

Chemical Film (Chromate Conversion): Provides a thin, conductive coating for corrosion protection and paint adhesion, often used in aerospace (e.g., Alodine).

Leading manufacturers no longer treat machining as an isolated step. The competitive advantage comes from vertical integration:

Design for Manufacturing (DFM) Partnership: Engaging at the CAD stage to suggest tolerance relaxation, fillet optimization, and material selection that can reduce cost and lead time by 30% or more without sacrificing function.

Digital Thread: Maintaining a seamless digital data flow from the customer's 3D model through CAM programming, machining, inspection, and into the quality certificate. This ensures traceability and enables rapid iteration.

Scalable Production: Utilizing automated pallet systems, robotic part loading, and lights-out machining capabilities to scale from prototype to high-volume production with unwavering consistency.

Precision aluminum machining is the silent enabler of technological progress. It transforms a versatile metal into the critical, high-tolerance components that define performance in the most advanced products on the planet.

Partner with a specialist who understands that precision is not just a tolerance on a drawing, but a philosophy embedded in every step of the process.

Challenge us with your most demanding aluminum part design. Request a comprehensive DFM analysis and quote.