Views: 0 Author: Site Editor Publish Time: 2025-12-27 Origin: Site

Electrostatic Powder Coating: The Smart Surface Solution for Modern Manufacturing

Powder coating has evolved from a simple finishing option to a strategic, high-performance surface technology. Beyond its renowned durability and environmental advantages, modern powder coating now integrates seamlessly with advanced manufacturing to deliver unprecedented quality, efficiency, and design flexibility. This evolution makes it an indispensable process for engineers and product managers demanding more from their finishes.

Why has powder coating become the finish of choice for industries from architecture to automotive?

Superior Durability: The cured thermoset polymer coating is highly resistant to chipping, scratching, fading, and corrosion. It consistently outperforms liquid paints in ASTM salt spray tests, often exceeding 1,000 hours without failure.

Economic & Environmental Efficiency: With near 100% material utilization (overspray can be collected and reused), waste is minimized. It contains no solvents (0 VOCs), eliminating hazardous air pollutants and reducing disposal costs and regulatory burdens.

Enhanced Quality & Consistency: Applied electrostatically, the powder naturally seeks out all charged surfaces, ensuring uniform thickness even on complex geometries, sharp edges, and recessed areas, which liquid paint might struggle to cover evenly.

Production Speed: A typical powder coating line has a faster cycle time than wet paint. Curing in infrared or convection ovens is rapid, allowing for quicker turnaround without sacrificing performance.

A successful finish relies on a meticulously controlled process chain.

Pre-Treatment (The Critical Foundation): This multi-stage cleaning and conversion coating process (e.g., iron or zinc phosphate) is non-negotiable. It removes oils, provides corrosion resistance, and creates a microscopically rough surface for ultimate mechanical adhesion. Skipping or compromising here guarantees coating failure.

Advanced Application: Modern electrostatic spray booths are marvels of efficiency.

Corona or Tribo Charging: Guns impart a negative charge to powder particles, causing them to be attracted to the grounded workpiece. Tribo charging is excellent for penetrating into "Faraday cage" recesses.

Automated & Robotic Systems: For high-volume or complex parts, programmable robots ensure flawless, repeatable application with zero human inconsistency.

Powder Recovery Systems: Sophisticated cyclone and cartridge filter systems reclaim over 95% of overspray powder for immediate reuse.

Curing Science: The final step transforms the powder into a continuous film. Precise oven temperature profiling is crucial—undercuring leads to poor performance, while overcuring can degrade the finish. Modern ovens with multi-zone control guarantee the exact thermal exposure needed.

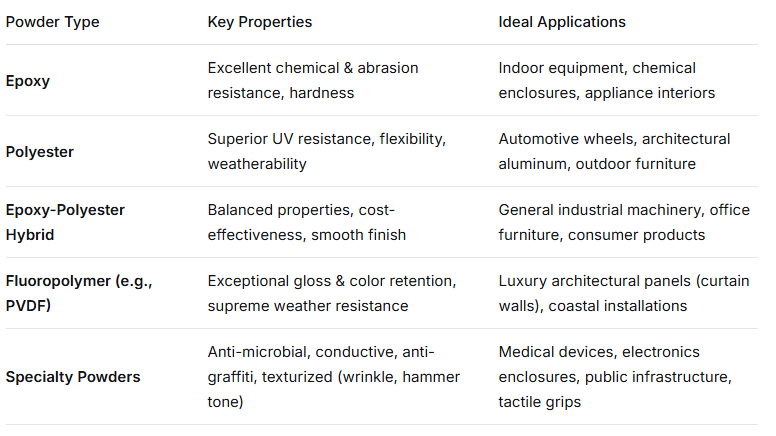

Today's powders are engineered chemicals designed for specific applications.

Architecture & Building Products: Provides the long-lasting, vibrant, and low-maintenance finishes demanded for aluminum extrusions, curtain walls, and window frames, meeting AAMA 2603-2605 performance specifications.

Automotive & Transportation: Used on wheels, chassis components, trim, and under-hood parts for its chip resistance and ability to withstand road salts, chemicals, and UV exposure.

Industrial & Agricultural Equipment: Protects heavy machinery from extreme abrasion, impacts, and corrosive environments found in factories, farms, and construction sites.

Consumer Goods & Electronics: Delivers the durable, high-quality aesthetic finish expected on appliances, fitness equipment, and electronic enclosures.

The next frontier is the fully integrated "Powder Coating 4.0" cell. This involves:

IoT-Enabled Monitoring: Sensors track booth humidity, gun kV/mA, oven temperatures, and conveyor speed in real-time, predicting maintenance needs.

Digital Color Management: Spectrophotometers integrated into the line provide instant feedback to ensure batch-to-batch color consistency beyond human perception.

MES/ERP Connectivity: The coating process becomes a data node, feeding quality metrics (film thickness, cure status) directly into the manufacturing execution system for complete traceability.

In an era where product performance, sustainability, and aesthetics are inseparable, powder coating is not just a finish—it's a critical component of product integrity and value.

Ready to specify the optimal coating for your next project? Our finishing experts combine material science with process engineering to deliver solutions that protect, perform, and impress.