Views: 0 Author: Site Editor Publish Time: 2025-08-06 Origin: Site

For forward-thinking manufacturers, precision isn’t just a goal—it’s the bedrock of automotive innovation. As electric and autonomous vehicles reshape the industry, CNC machining has emerged as the silent powerhouse enabling breakthroughs in performance, efficiency, and design. Here’s how advanced CNC technologies are redefining automotive manufacturing.

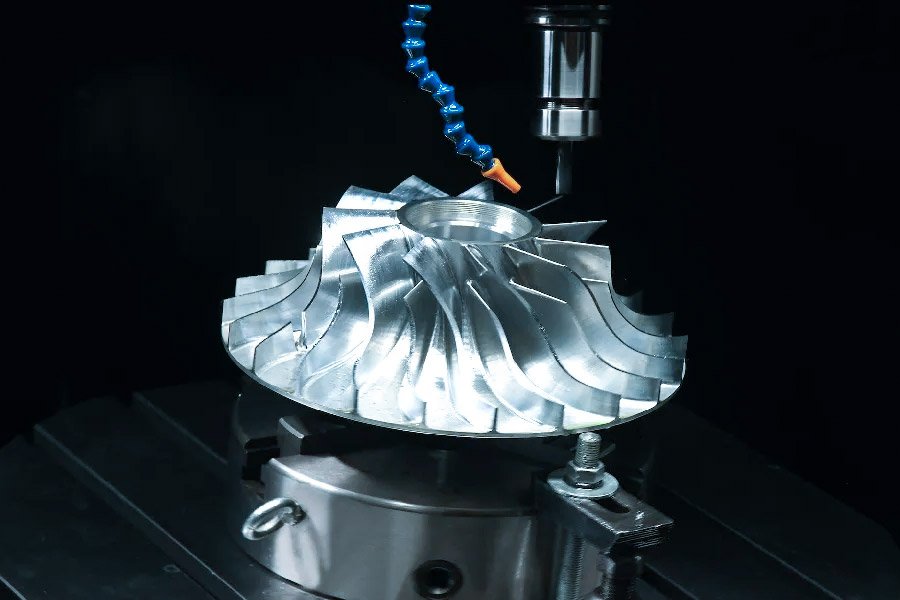

1. Five-Axis Mastery: Solving Complexity in Critical Components

Modern automotive designs demand near-impossible geometries—from sculpted engine blocks to lightweight structural parts. Five-axis CNC centers excel here by enabling:

Single-setup precision: Machining complex angles (via A/C rotational axes) without repositioning, slashing errors for components like turbocharger housings or transmission cases

Micro-tolerance dominance: Holding tolerances as tight as ±0.0005 inches (0.0127 mm) for fuel injectors, valve seats, and hybrid drivetrain parts

Material versatility: Seamlessly processing aerospace-grade aluminum, high-strength steels, and engineered thermoplastics (e.g., PEEK for sensors)

2. Speed Meets Accuracy: How High-Performance CNC Systems Redefine Efficiency

Legacy production lines can’t match today’s AI-enhanced CNC systems. Key advances include:

High-dynamic machining: Linear acceleration up to 1G and rapid feeds of *60 m/min* minimize idle time, crucial for high-volume engine block lines .

Closed-loop precision: Real-time error compensation achieves positioning accuracy under 5 μm—critical for camshaft lobes and bearing journals .

Zero-defect safeguards: Integrated tool-breakage detection and in-process gauging scrap rejects before they happen .

3. Cutting-Edge Tooling: The Unsung Hero of Automotive CNC Innovation

Tooling breakthroughs directly impact productivity:

Ultra-hard materials: CBN (cubic boron nitride) and PCD (polycrystalline diamond) cutters enable dry machining of cast iron blocks at 800+ m/min surface speeds, doubling tool life .

Nano-coatings: TiAlN layers reduce friction by 40%, extending insert longevity during high-temp alloy machining .

Smart composites: Combining drilling, threading, and chamfering into one custom tool trims gearbox production cycles by 30% .

4. Electric & Autonomous Vehicles: CNC’s New Frontier

EVs aren’t just changing powertrains—they’re rewriting machining rules:

Battery/fuel cell systems: Water-cooled plates (machined from conductive copper alloys) and PEM electrolyzer stacks require leak-proof tolerances <10 μm .

Sensor ecosystems: Radar housings (from RF-transparent PTFE) and LiDAR mounts demand vibration-free finishing .

Lightweighting breakthroughs: CNC-milled carbon-fiber tubs and aluminum suspension knuckles shave 15%+ weight vs. steel .

5. The Future Is Here: AI, Digital Twins, and Sustainable Production

Leading factories already leverage:

Predictive machining: AI algorithms forecast tool wear, cutting 30% unplanned downtime .

Digital thread integration: CAM-to-CMM data loops enable real-time corrections across engine block lines .

Zero-waste workflows: Swarf recycling and optimized nesting boost material use to 98%+ .

“The engine line’s switch to five-axis CNC cut our cylinder head machining time from 18 hours to 4.7—with zero scrap in Q1.” — Automotive Tier 1 Supplier Case Study

Your Next Move

As electric vehicle production surges (projected 30% CAGR through 2030), manufacturers replacing legacy systems with adaptive CNC cells will dominate. Whether you’re machining battery trays or AI-driven sensor arrays, the right precision partner makes the difference.

Ready to upgrade your production line?

Explore turnkey CNC solutions for torque-dense EV gearboxes, fuel cell bipolar plates, and autonomous vehicle hardware at www.holyprecision.com.

Accelerate tomorrow. Machine precision today.